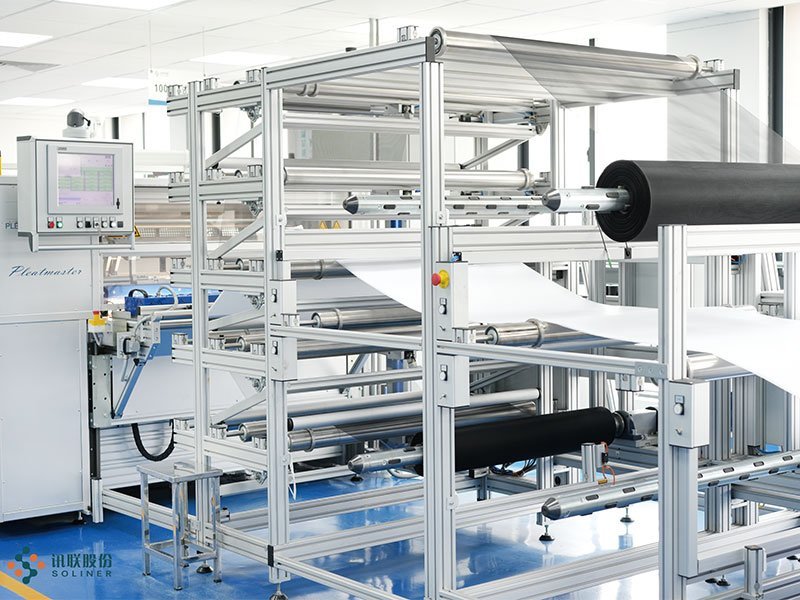

Advanced Machining Center

Soliner is a manufacturing enterprise with multiple production workshops, including machining, temperature-controlled solenoid valve, temperature-controlled honing, sheet metal, filter, and hydraulic assembly workshops. We are equipped with professional intelligent production equipment such as Mazak flexible production lines, Japanese intelligent processing unit islands, German original forming grinders,German original double-end face grinders, and German Roboski filter production lines.

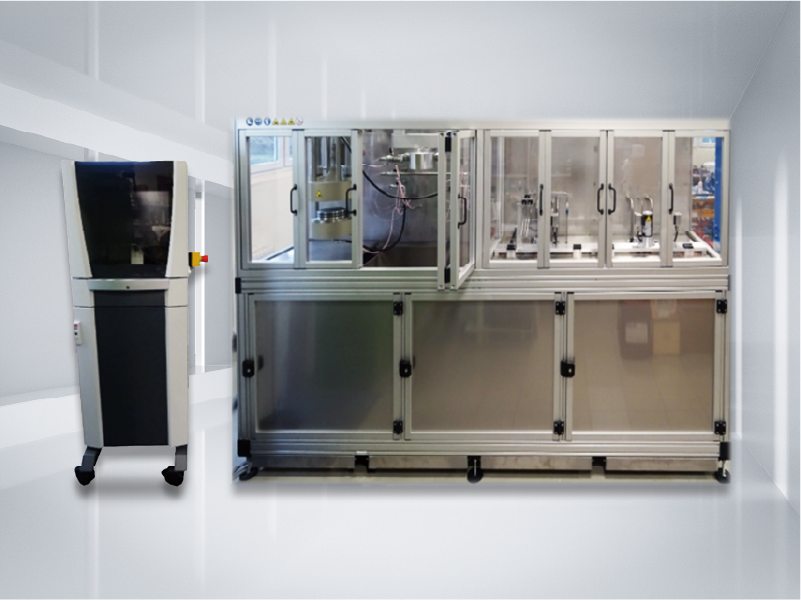

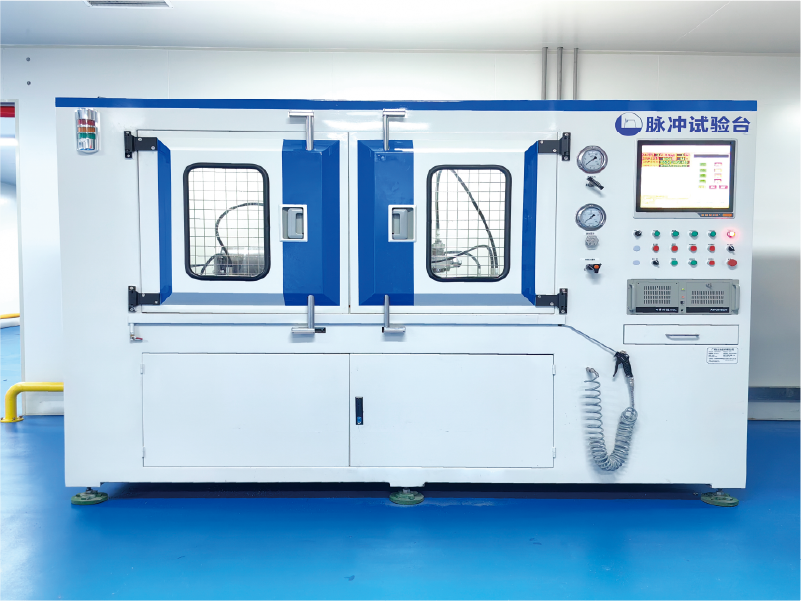

Technical Testing Center

Soliner has a total of 3200 square meters of various type of laboratories,including comprehesive performance of wind lubrication systems, high and low temperature testing, hydraulic filtration, heat transfer performance of coolers, it also has a large number of outstanding technical personnel and a comprehensive product development system.

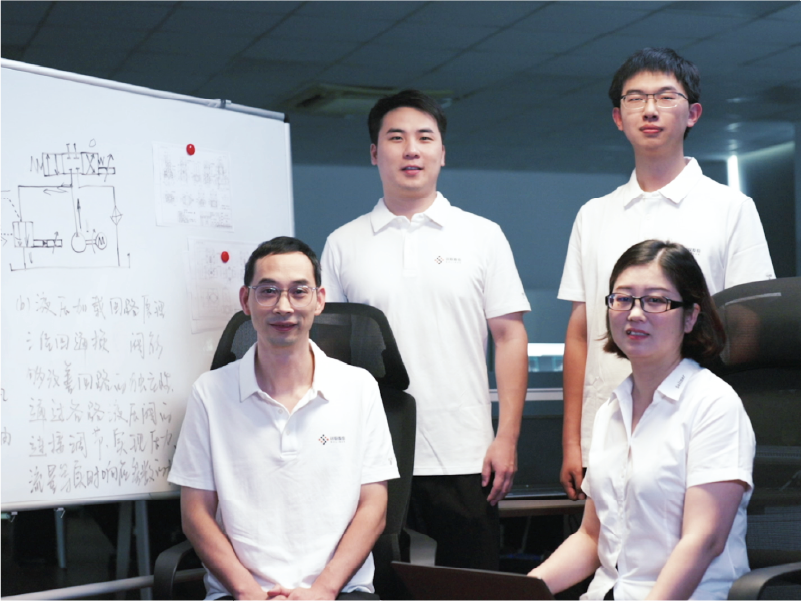

Technical Team

Led by senior engineers, our top-tier R&D team upholds exacting standards and refines every product to perfection. Over 200 production staff, equipped with modern machinery, secure strong output, while our full-cycle QC system-covering incoming, in-process and final inspections-guarantees each unit leaves the plant as a premium product.